Director's Brief

by Byron Wolff

Welcome to Thompson Longhorn’s December newsletter. As the company is continually expanding and innovating, we like to keep our loyal customers up to date with what we are up to and what is new. In the past few months, Thompson Longhorn has been focusing on providing a better customer experience to all of our valued clients.

We have been working tirelessly to give our antiquated website a much needed face-lift and have also taken the opportunity to make it mobile friendly. There is a lot of work yet to be done but it does look pretty schmick. We are very excited about this update because our content is now more readily accessible to people on the move. It is also now much simpler for us to create and add new content to the website, so keep an eye out for any changes.

We have also been working on training our sales team to collect better data from site. Part of this development is a targeted questioning system which ensures that critical information is captured with maximum accuracy, minimising the amount of time wasted with potentially incorrect assumptions. Combine this with the addition of a new drone for aerial photography (with a higher resolution camera) and site data collection will be even simpler.

As this is the last newsletter for the year, I would also like to thank you for your business, support and friendship throughout 2015. Hopefully you all have an enjoyable break over Christmas and I look forward to hearing from you in the new year.

Thompson Longhorn Factory Tours

288 Inverramsay Road, 74 kilometres from Toowoomba

Have you ever visited the TL factory? We welcome you to visit us to see our automated trade display and our robotic welding facility. Our factory is only a 50 minute drive from Toowoomba. Simply turn east just south of Allora at the Goomburra turnoff and 12.5 km later you will be at Thompson Longhorn.

Automated trade display at our factory

Our opening hours are 8.00am until 5.00pm Monday to Friday.

We will however be closed over Christmas from 24th December to 10th January.

An appointment is necessary for factory tours. To book an appointment please call us on (07) 4666 6174.

Thompson Longhorn,

288 Inverramsay Road,

Goomburra Qld 4362

Uaroo Station - Project Exclusive

by Emily Dalziel

Earlier this year we were responsible for the detailed design, fabrication and supply of an automated handling facility and accompanying feed pens on a remote greenfield site at Uaroo Station near Onslow, in WA's Pilbara region. For this project, Thompson longhorn provided a supervisor to work with the station staff and manage the on-site installation.

Towards the end of October, we trekked across the country to see how the new yards were going. We shot some great footage with our drone, interviewed the stockmen and watched the loading of a triple road train.

Loading of a Triple Road Train

"We decided to go with Thompson Longhorn because we were impressed with their attention to detail and the advanced design of their equipment. The company is focused on labour saving design and safety. They worked with us to develop a plan that suits our requirements and environment. The end result is a great set of yards that we're really happy with." -- Ben Wratten, Station Manager, Uaroo Station WA.

Uaroo Station - Feed Yards

Designed to minimise labour requirements, the new yards at Uaroo have permanently removed 2 labour units, yielding an annual saving of approximately $100k. Add to this saving the reduction of workplace accidents and associated loss of productivity and the project no longer looks like an expensive undertaking, but a worthwhile investment.

As a closing question to the visit, Wratten was asked if he would recommend Thompson Longhorn to a friend. He responded with a grin: "I already have."

Featured Product - Sorting Systems

by Kelly Keong

Moving a swinging gate in a cattle yard without actually having someone in the yard on foot is always a good idea. My great grandfather worked out that a pound drafter with a crow’s nest was a great way to achieve this. These days there are much better ways to move gates remotely than using platforms with rod levers or cables. A good place to start is still with sorting gates. Thompson Longhorn automate the sorting gates in both lane and pound type drafters. The most common sorting systems these days is the lane type drafter.

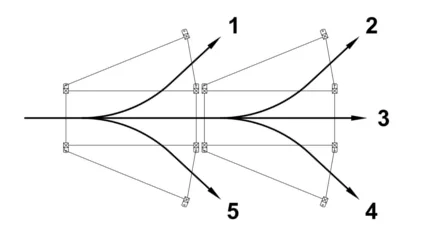

Lane Draft - 3 Way Fan

If making your living finds you, your family or staff sorting cattle on a regular basis, you should consider investing in a pneumatic drafter (if you don’t already have one). The benefits in both operator safety and labour saving are immediately apparent. The design of this equipment must also be considered (uncomplicated as it is) to maximise animal safety. If you do not want to take my word for it, I suggest you do some research. It is always a good idea to talk to someone who already has a pneumatic drafter. I know you will be hard pressed to find someone who regrets buying one.

Lane Draft - 5 Way Fan - Schematic

Thompson Longhorn often refers to our lane drafters as Fan drafters. This is because the plan view of one is shaped like a fan. The unique shape comes from the “wing panels” on either side of the central lane (which is a standard feature on every module). The wing panels lead into the pens to which the animals are being sorted. Combined with the correct length of sorting gate, this reduces the possibility of hip or shoulder bruising while sorting your cattle.

Draft Automation Control Box

If you press a button on a handset and a sort gate opens for you, then you are controlling your drafter “electronically”. This technology is quite simple, very good value and robust. It is also the first step in the process to use NLIS tags to automate intensive animal operations such as sorting and to take advantage of the management tool that this can be. The reality is that even if your operation is never going to automatically draft animals using a “smart scale monitor” or herd management software, just making the gate operate remotely will be a revelation in itself.

Intelligent Yard Design

by Chris Nielsen

Designing cattle handling yards is simple, right?

The majority of cattle handling is performed in purpose built yards. These yards are expected to be highly versatile. They are utilised to perform various tasks, ranging from loading trucks to pregnancy testing. Identifying the range of tasks that need to be performed and designing a set of yards that best caters to them, is where Thompson Longhorn has proven experience. Our rigorous design process ensures that all required tasks and potential oversights are accounted for, making well planned yards even better.

Cattle Being Tagged

The Thompson Longhorn design process involves many steps, starting with the collection of your requirements and details. For this initial step, we ask a set of targeted questions that maximise the data collected in minimum time, enabling us to start the yard design process with the knowledge of the correct yard size and handling equipment. Next we collect site photography (where possible), including aerial photography with one of our camera drones. For more information, see the article in our September Newsletter: "Drones – Above and Beyond". From this data, we can then confidently recommend the next course of action: standard TL design or custom design.

Gathering Site Information

Standard TL designs are well optimised and designed yard plans from our catalogue. This avenue presents many benefits including the incorporation of great design, being deliverable in the shortest possible time frame and the ability to easily "clip in" some additional features.

Custom design leads us on to the true investigation of your existing and future requirements. We take a step by step approach to the operations that are performed in your yards and customise a process flow document to suit. This document helps to identify and clarify functional requirements that you may not have considered. A conceptual yard design is then created to suit your requirements and the process flow document. This concept is a realisation of the required tasks in yard layout form, showing fence lines and handling equipment. The yard layout concept is then tweaked, ensuring the process flows are efficient and the requirements are met, until your preferred design is obtained.

Computer Generated Yard Concept

As it turns out, there is actually quite a bit of thought and meticulous process behind every cattle handling yard, especially if you want it to be as efficient as possible. Maybe it isn't as simple as just a few panels and gates after all?

Quick Links

288 Inverramsay Road, Goomburra Qld 4362, Ph: (07) 4666 6174, Fax: (07) 4666 6242, www.thompsonlonghorn.com.au